Of buses and batteries

The wheels on the bus go round and round…and more and more of them are powered by batteries.

Buses were by far and away the most likely vehicles to have adopted battery power, because of their fixed routes and the predictable demands they consequently made on batteries. If battery power worked for buses then other vehicles might have followed suit. In the grand scheme of things, the failure of an electric bus may seem trivial, but it ultimately led to the failure of electric delivery vehicles. The result was a resounding victory for the internal combustion engine, which in turn established acceptable levels of noise and pollution. We still hear and breathe these consequences today.

From the introduction to A Most Deliberate Swindle by Mick Hamer (ISBN: 9781910453421).

The story of the London Electrobus Company and its demise, brought about by the financial chicanery of Edwardian charlatans in 1909, makes fascinating and entertaining reading. But even though the electric bus mantle was picked up again by London United Tramways in 1931 in the form of trolleybuses (which ran in London until 1962), by then the internal combustion engine was the ICE king. We can only speculate on how far on we’d be with electric vehicles today, had electricity won the day over petrol back in those naughty nineteen-noughties.

Ah well, there it is, we are where we are. Today, the drive for net zero emissions from buses and coaches mainly comes from two sources. First, there’s the legal requirement to reduce greenhouse gas emissions and raise air quality1. Second, there’s the drive to boost active urban mobility. As an example, London is targeting to achieve 80% of trips by foot, cycle or public transport by 20412. On the back of this, we’re seeing lots of net zero bus projects across the UK, as well as the rest of Europe and pretty much all the other major cities of the world. And the projects are growing in scale.

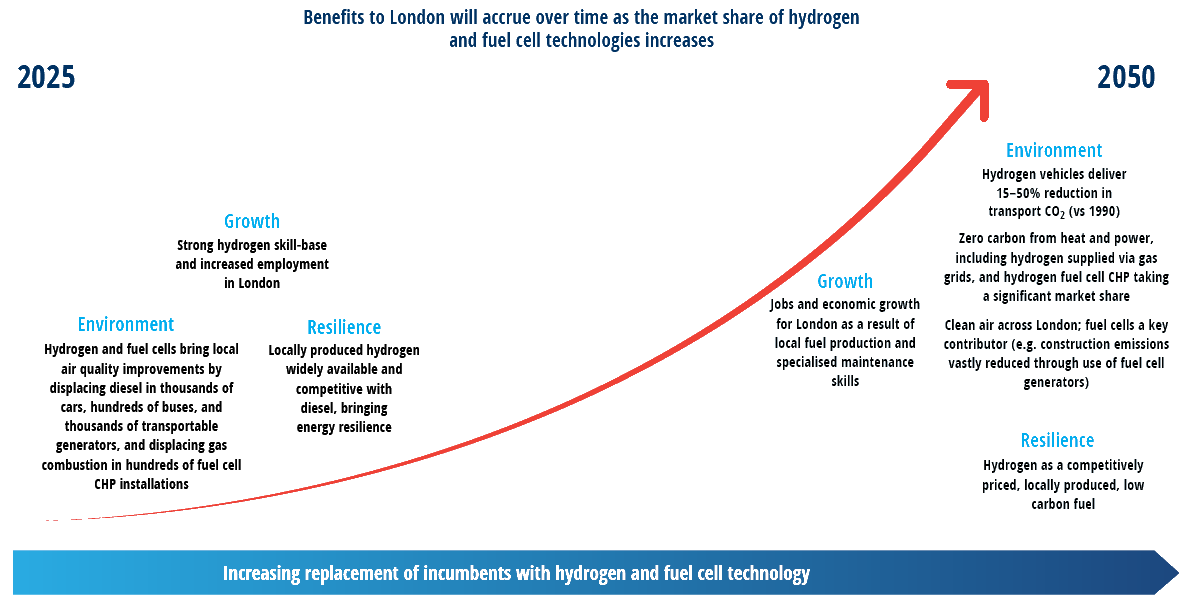

At time of writing, there are around 920 zero emissions buses and coaches in the UK. The greatest number is in London (around 600), but there is also an extensive set of projects in Scotland. The numbers are growing, but this is still a small proportion of the total - 72,000 buses and coaches in total are registered with the DVLA3. While most zero emission buses are powered by batteries, we also see hydrogen featuring in places like Aberdeen, Birmingham and London. In fact, Hydrogen London is clearly seeking to create collaborations to drive the market forward and support its future development - its 2016 report saw potential for local hydrogen production and the development of specialised maintenance skills.

Source: Hydrogen London / Element Energy, 2016

The wheels on the bus…

At the outset, it’s important to realise that the cost of the battery attached to the wheels on the bus is around one-third the total cost of the bus itself. So, a high-value asset like that should be kept in tip-top condition. According to Zenobe, factors determining battery performance include: the efficiency of the depots; charge optimisation; driver behaviours; management of non-battery vehicle issues; and routing.

The skills implications here are clear. The efficiency of depots depends on how well they’re organised and operated; driver behaviours include changes to acceleration, breaking and cruise patterns, all of which require some element of retraining; and low energy routing involves geographic and topographic skills - with digital support - to plan routes around factors like dynamic traffic patterns and minimised gradients4.

In its 2021 report, The European Bank for Reconstruction and Development (EBRD) provided some insight into the shifting skills base for bus and coach maintenance. It suggests that engineering processes will change and assumptions on engineering costs - which represent around 10-12% of the typical all-up diesel bills - should be updated. It says:

…there is good reason to assume that a substantial cost reduction of 10-30 per cent may be possible, depending on local assumptions. However, change-management programmes are essential to delivering the potential savings through retraining and headcount reductions.

Hang on, though. Headcount reductions? The Green Edge notes that the cost analysis contained in the report assumes that the number of staff required to maintain an electric vehicle coach remains the same as diesel, at 8 buses per maintenance person. Talking about headcount reductions seems to us to be a little odd, particularly in view of the job creation claims being made by governments for the net zero economy.

…go round and round…

There seems little doubt that keeping the wheels of e-buses and e-coaches going round and round will significantly change the types of maintenance required. Notwithstanding its comments on headcount reductions, here the EBRD report is quite helpful:

Image: BMI adapted from EBRD

The report also makes the good point that the power and charging equipment itself will require maintenance and this may need to be outsourced. In fact, this is part of a whole new set of operational and business models around battery management, including battery-as-a-service and circular economy models where companies like Zenobe are leading the charge (we’re by no means the first to ask if you’ll pardon that particular pun).

Another group looking closely at the skills impacts comes from Scotland, where the Bus Decarbonisation Taskforce envisages a future in which “[e]nergy networks, bus operators and Local Government are used to working together to ensure depots are powered/fuelled and all potential users are able to benefit from the energy provision centred at depots and on-route charging infrastructure”. The taskforce also dutifully ticks the circular economy box by adding to its future vision, “[b]uses and infrastructure are fully recycled at the end of asset life”. Just recycled, then, Scotland? No plans for reuse or pepurposing?

The Institute of Apprenticeship and Technical Education (IfATE) is starting to run with the baton too, as we see standards such as Bus and Coach Engineering Technician being revised. But we do hope that IfATE does a bit of its own circular economy thinking here: there’s useful curriculum content around battery build and test in the Propulsion Technician standard which could well apply to the Bus and Coach Engineering Technician standard, for example.

…all day long

A shift towards e-buses is happening in most of the towns and cities driving the UK’s public transport system and employing the bulk of its 10,000 or so maintenance staff. Along with the skills shifts for maintenance people, drivers - around 130,000 of them - will also need retraining to adopt new driving behaviours.

Knowledge of the skills needed is nothing new. Remember, electric buses go back over a hundred years. It is worth noting though that while there is a long list of European traditional bus and coach manufacturers, the powerhouse country for electric buses and coaches is China (where else?). China’s top 10 e-bus producers deliver nearly 52,000 units a year globally and have amassed a wealth of experience in e-mobility over the last 20 years. Yutong alone has 122,500 zero emissions vehicles in use, with 25.6 billion zero emission kilometres on the clock.

And companies like Yutong are important here. If you’re a bus company procurement officer (or a green-minded parent with a fat wallet and a very large family) the bus you might buy from Pelican Engineering comes from a joint endeavour with Yutong, in which Yutong provides the core 70% and Pelican does the rest. In this case, Yutong also provided training to the local staff.

We are now at the crossover point to 2030. It almost goes without saying that we need to be cracking on with things. The retraining programmes and appropriate standards all need to in place to build the infrastructure and skills base for a smooth transition to zero emissions transport. As ever, The Green Edge is watching with interest. All day long.

Just one thing before you go. The Green Edge is looking for sponsors. Your sponsorship may be linked to a specific piece of content, a steer you would like to give us, or simply in recognition that we are adding value to the green skills narrative. It could be at any level, perhaps as a one-off contribution or maybe in more regular instalments. Most likely, we anticipate your sponsorship would be on behalf of your organisation. At whatever level, your support will be valued by us and will help us greatly with our plans for developing The Green Edge. Thank you.

For a sense of perspective, it’s perhaps worth noting that in the UK, buses and coaches produce 3.2 Mt CO2e. This is only 3% of the total emissions from road vehicles.

…which, we have to say, does seem to conflict somewhat with the current fixation on introducing eScooter schemes across the Capital. Perhaps capital (with a small ‘c’) has a certain influence here.

Source: Zemo Partnership, 2020

It’s interesting to note that the much-hyped (at the time) delivery trip on Easter Sunday 1908 for the first electrobus sold outside of London - to Brighton - resulted in the vehicle catching fire due to an overheated rear axle. The reason was probably the additional weight incurred by the extra battery needed for the 52-mile journey. The combined weight of the two batteries was 3.5 tonnes.